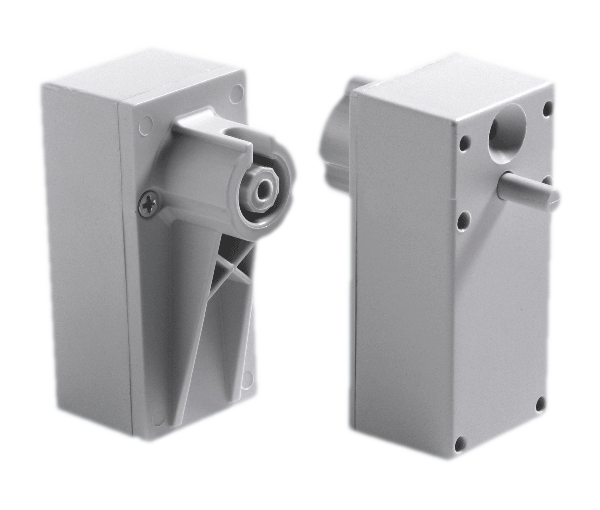

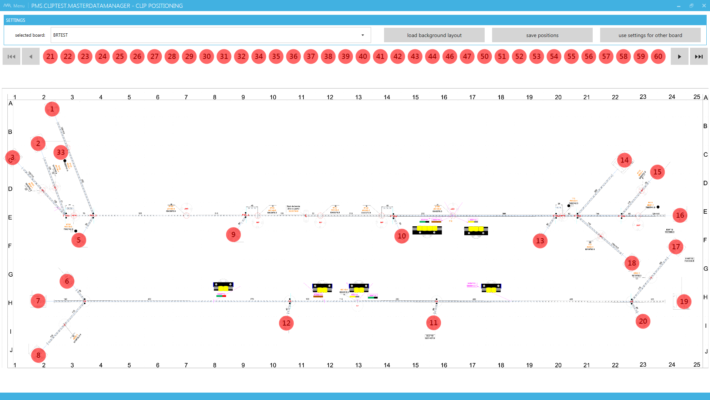

PMS.Cliptest is software that, in conjunction with special switches, enables these mechanically actuated buttons to be recorded and analysed without wiring. This solution can be used wherever the presence of mechanical attachments needs to be checked, for example in cable harness production. The attachments are registered via small wireless switches on the assembly or test boards. No wiring work is required on the boards for the system setup, which greatly simplifies and speeds up going live.

Automated inspection of assembly in this way saves time compared to manual inspection and reduces the error rate in the long term. The automatically generated production documentation also supports your quality management documentation obligations.

PMS.Cliptest has been in use worldwide for over 15 years and is constantly being further developed. A personal support rounds off the product PMS.Cliptest.

What can PMS.Cliptest do?

The energy required to generate the radio signal is generated from the mechanical movement - by energy harvesting - of the switch. A test list is stored for the respective product (e.g. cable set or cable set type). The running test for a harness then validates the received state of the switch against this checklist. A test list can be created manually and then imported or received automatically by a leading system via the available interfaces.

This means that testing is also possible for one-off production. The current status of a running test can be displayed at any time on one or more screens in different visualization forms. The software also has interfaces to the process so that event-related reactions or actions can be taken with the aid of a control system.

Core functions

- High-performance tests with more than 500 switches per mounting/test board

- Empty test of assembly/test boards

- Control of the application by one or more barcode scanners

- Distributed, networked display across multiple workstations

- Printing of test labels or test reports

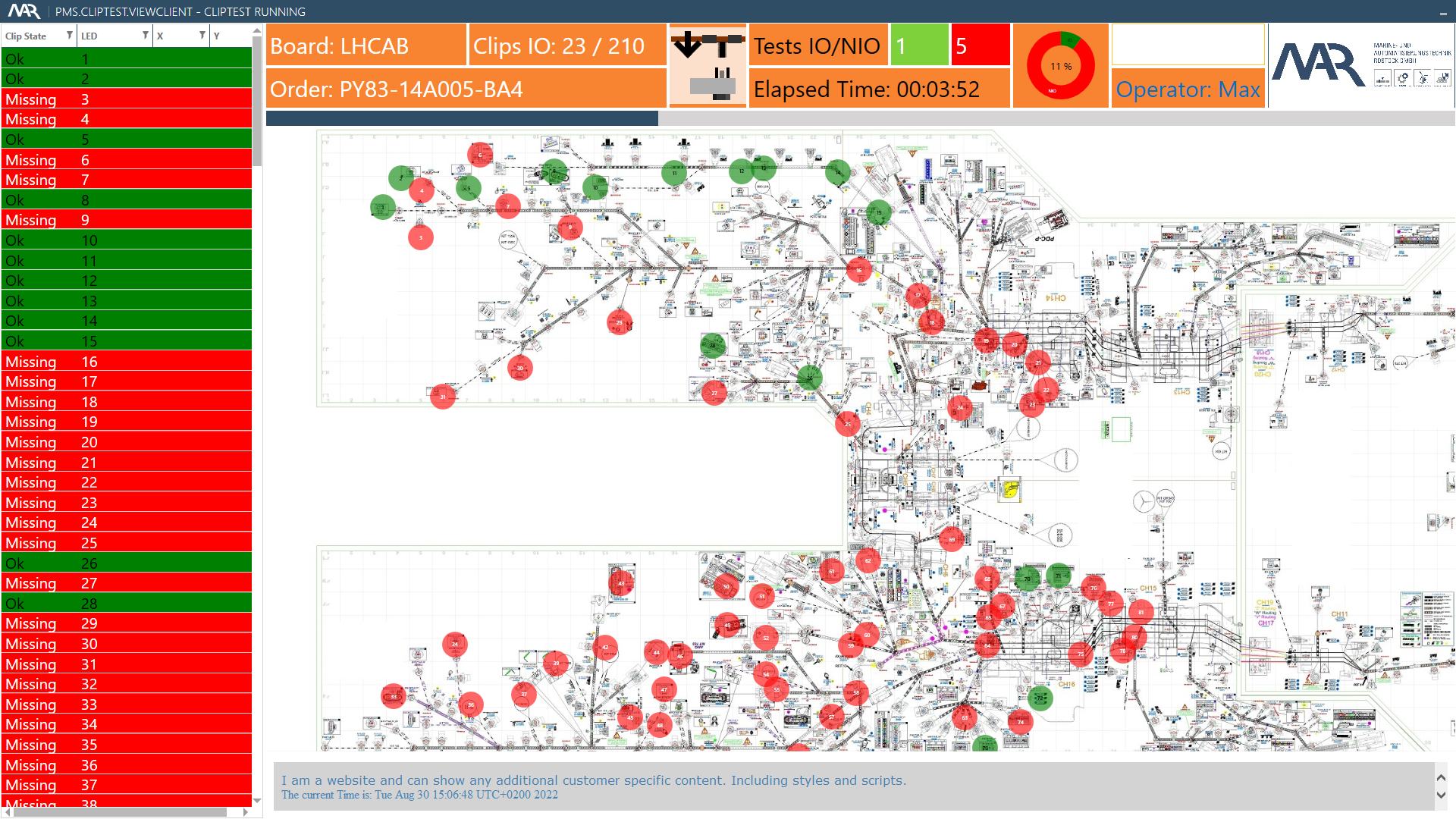

- Flexible and versatile visualization of tests - graphical, tabular or both at the same time

- Multi-monitor support

- Simple, guided maintenance of configuration data

- Interfaces to other MES/ERP systems

- Integrated Web API for external data retrieval

- Generation + storage of test results

- Licensing via USB dongles - Offline and machine independent

- All functions can be tried out with the 50 days demo license (on request)

Extensions

PMS.Cliptest.Eventing:

- Offers extensive possibilities for automation via linking of events with actions

- Connection of various hardware and control systems including OPC-UA client

- Process-dependent control of inputs and outputs

PMS.Cliptest.Dashboards:

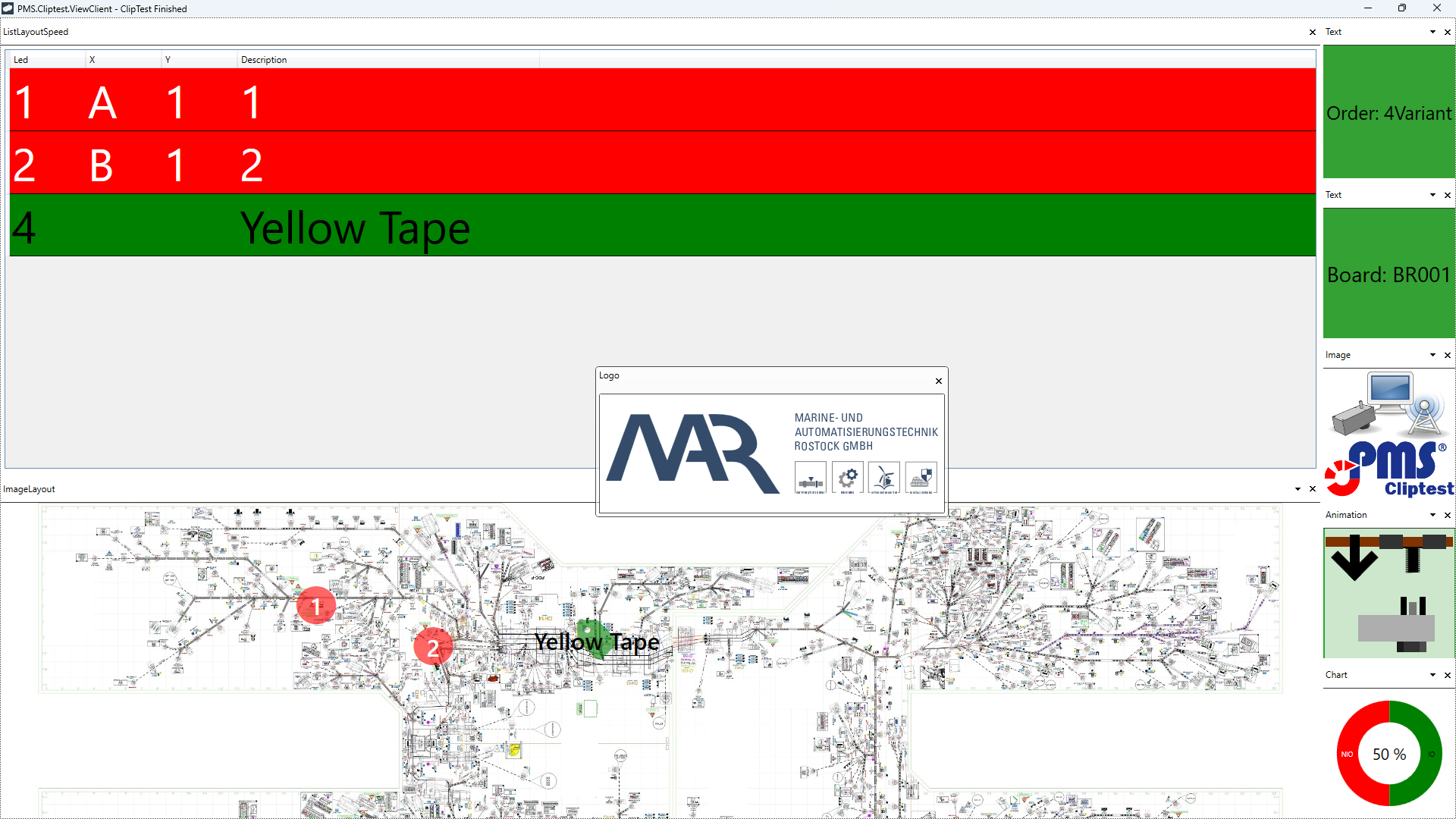

- Design your own visualization for optimum production support

- Arrange components using drag & drop

- Show enhanced information, embed images or integrate websites

PMS.Cliptest.Reporting:

- Advanced generation of statistics

- Overview of all switches and frequency of operation (predictive maintenance)

- Overview of the number of tests with regard to boards, orders, workplaces and time periods

PMS.Cliptest.Masterdatamanager Extensions:

- Enables the exchange of switches during running production (Clip Exchange)

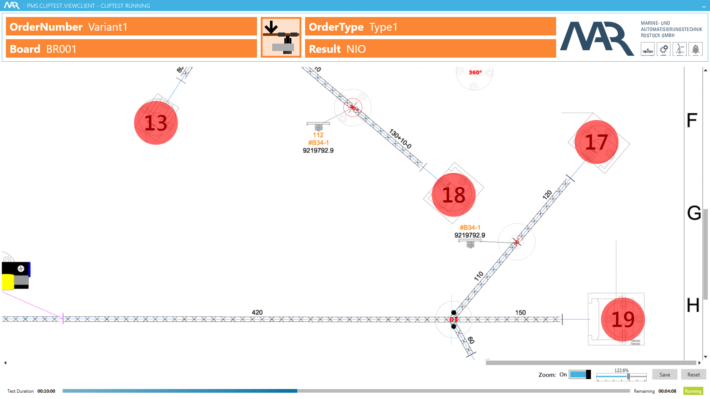

- Guided creation of configuration data (board teaching)

- Simple switch exchange by means of scanner or switch actuation

worldwide installation sites

Installations

Pushbuttons per installation

h/ year Labour time savings due to wiring changes in the cable harness layout

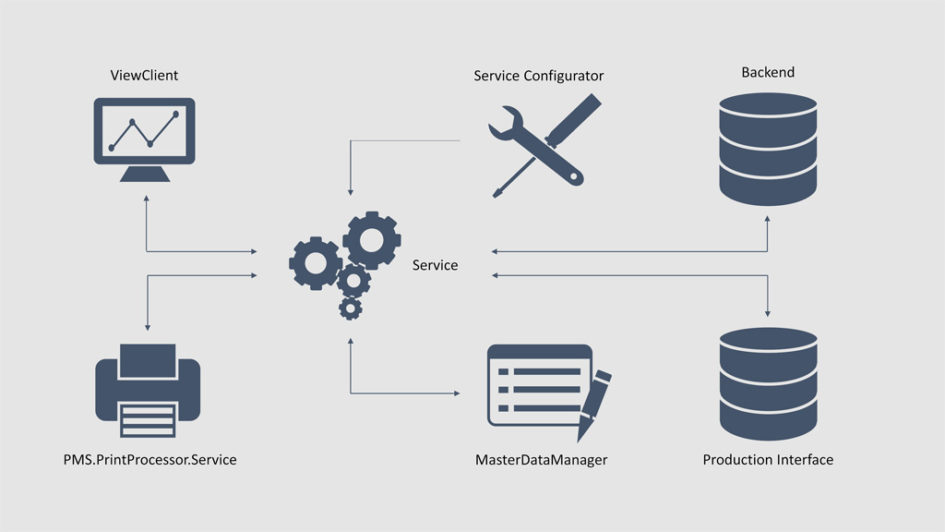

THE SOFTWARE Components

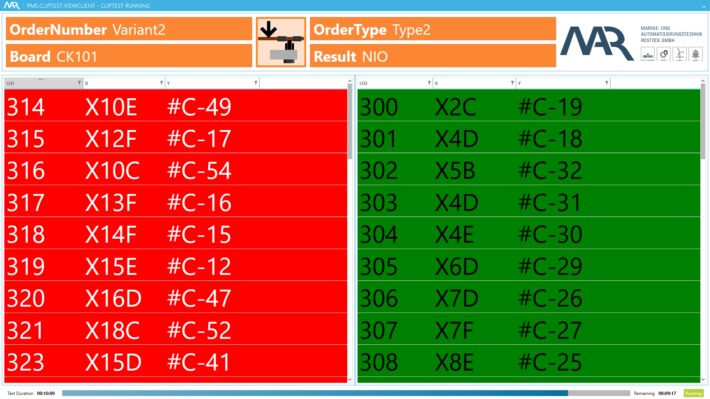

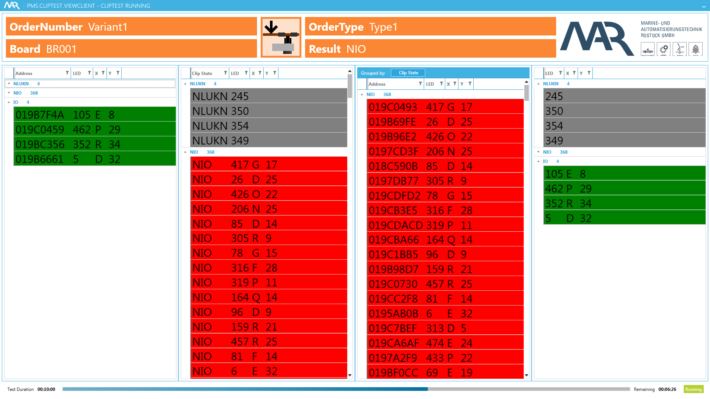

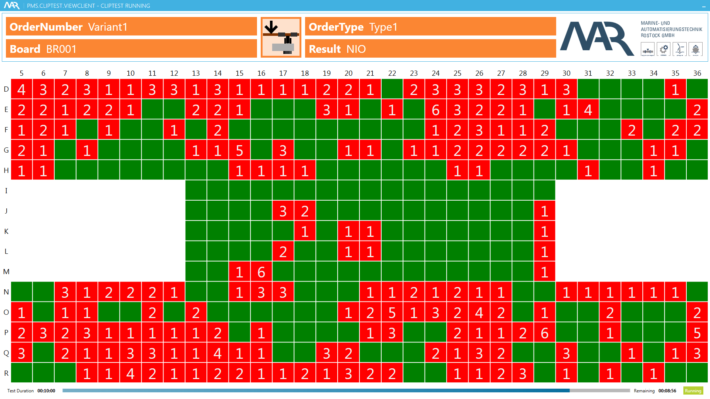

ViewClient

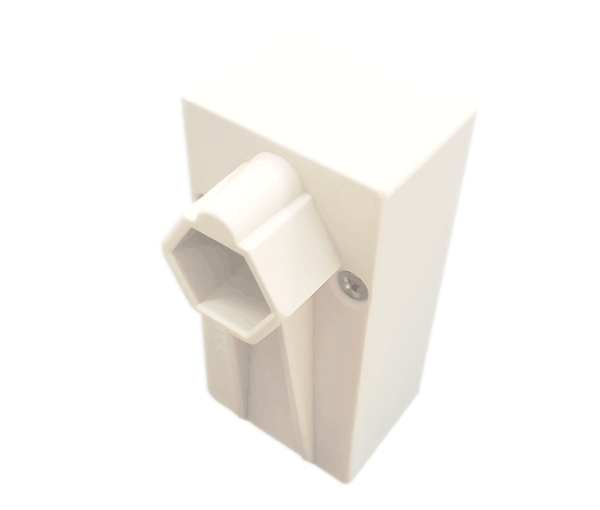

The ViewClient displays all information about a running test in different visualizations.

PMS.PrintProcessor.Service

The PMS.PrintProcessorService is responsible for printing labels in PMS.Cliptest.

Service

The service component manages the test logic as well as the communication with test hardware and other connected systems.

Service Configurator

The ServiceConfigurator is used to edit and test the settings of the service.

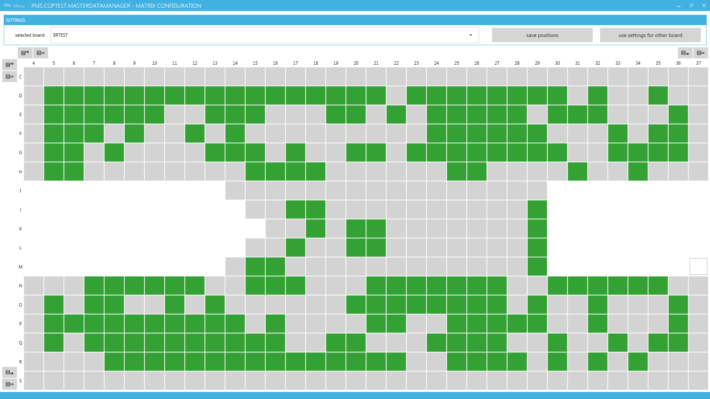

MasterDataManager

The MasterDataManager provides functions for importing, editing and deleting the required master data. It also allows the teach-in of the function switches.

Backend

The backend stores all the data required for a check, such as the board configuration, the checklists and the switch states. Either a database or the file system serves as the backend.

Production Interface

The optional production interface seamlessly integrates PMS.Cliptest into customer-specific production management systems.

Visualisation

Image Visualization

- An image can be configured as background

- Wireless switches are placed by drag-and-drop

- Zoom function for detailed views

Grid visualization

- Filtering, sorting and grouping of the wireless switches

- Up to 7 areas can be used

- Show, hide, and arrange columns in any pane

Matrix visualization

- Based on the radio switch coordinates

- Definable section areas

- The numbers show the number of radio switches missing for the test in each field

Dashboard visualisation

- Defining your own views

- Import and export defined layouts

- Integration of key figures and your own reports

Do not hesitate to contact us if you are interested in PMS.Cliptest. We will be happy to arrange an online presentation with you. In addition to the detailed documentation, we also offer training courses on the use of the system. These can be conducted online or as a face-to-face event.

Downloads

1. Documentation PMS.Cliptest

2. Documentation PMS.PrintProcessor.Service

3. Quick Start Guide

4. Setup PMS.Cliptest

* V24.1.3.0 | * Demo license must be requested

(MD5: 5cea2cce981e9f1f0b3e260745e63a9b| SHA1: 4d97579dfd326e76f0b0808b745fb0804739f0e4)

5. Setup PMS.PrintProcessor.Service

* V3.2.4.0

(MD5: a8df354d17c9127b127e6d47260b7790| SHA1: cdf55c3d3b0409025a1470d49d548dc4f9b54100)

* Requirement Microsoft Visual C++ 2015 Redistributable

* Requirement Microsoft .NET Framework 4.7.2 Offline Installer

PMS.cliptest from MAR Rostock

Just contact us.

Marine- und

Automatisierungstechnik

Rostock GmbH

Hundsburgallee 9c

D - 18106 Rostock

Phone +49 (0381) 86509 0